2022-02-12 The lost wax method simply consists of replicating the object to be cast in wax, then immersing it in a pool of sand/powder and leaving it to dry, so that the wax replica is covered with a sand coating. The wax replica is then covered with a sand coating and the procedure is repeated until the coating is sufficient to support the casting process, after which the wax is melted from the mold and withdrawn from the mold. The mold then needs to be heated several times to increase the hardness before it can be cast. This method has good accuracy, but is quite costly due to the high price of the sand/powder and the complexity of the production process, which requires several heats. expensive.

Read More

2022-04-27 The surface of the wax mold is covered with a layer of refractory ceramic material. Once the ceramic material hardens, the desired casting geometry is formed inside it, and then the wax is melted and exported, and the cavity is filled with molten metal. After the metal solidifies in the ceramic mold

Read More

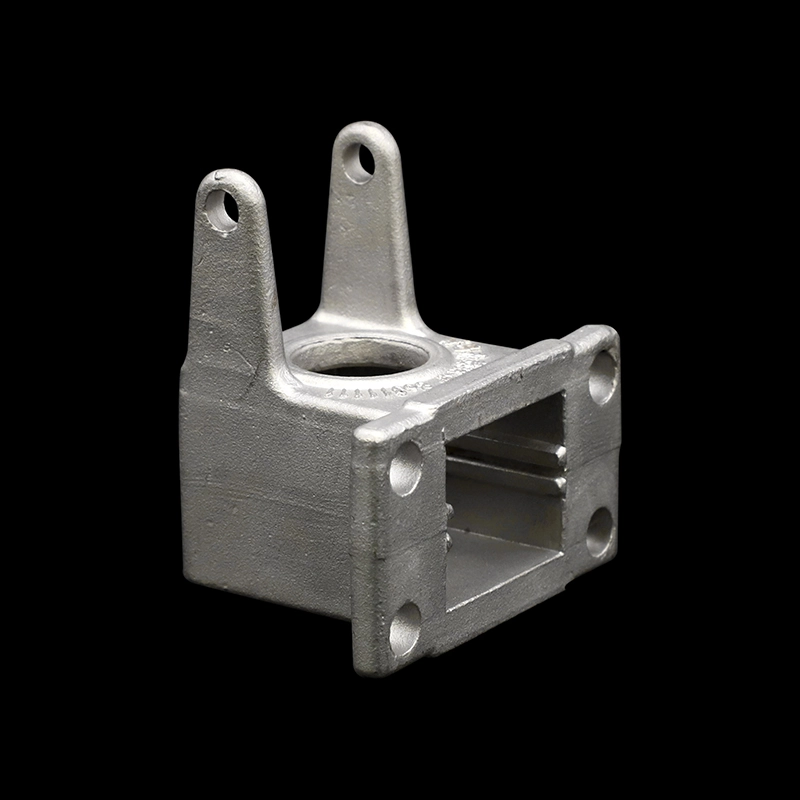

2022-04-26 Die Casting Part is a kind of pressure casting part. It uses a pressure casting machine die casting machine equipped with a casting mold and pours metals such as copper, zinc, aluminum, or aluminum alloy heated to a liquid state into the feeding port of the die casting machine. Machine die casting,

Read More

2022-04-27 The process and precautions of investment castingInvestment casting, also known as lost wax casting, includes processes such as pressing wax, wax repairing, tree forming, dipping, melting wax, casting molten metal, and post-processing. The currently popular Investment Casting Die Casting with Zinc/A

Read More

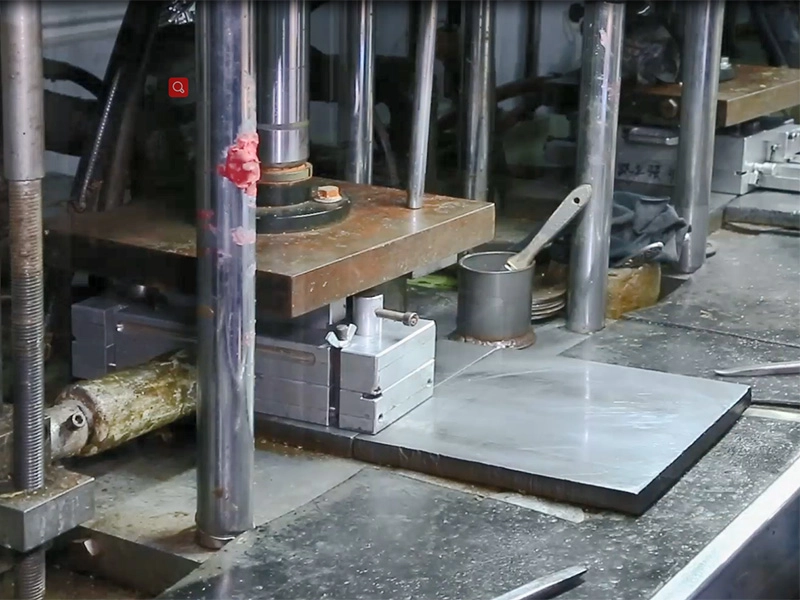

2022-04-28 To take out the model before pouring the metal, Sand Casting should be made into two or more parts; during the mold making process, holes and vent holes for pouring metal into the mold must be left to synthesize the casting system. Sand Casting keeps the metal liquid for an appropriate time until th

Read More